The lack of full digitalization in the Quality Department of the manufacturing industry can be attributed to various factors. While advancements in technology have transformed many aspects of manufacturing, several challenges continue to hinder complete digitalization in quality management (adopt QMS software). Here are some top reasons:

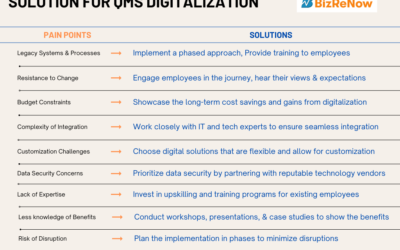

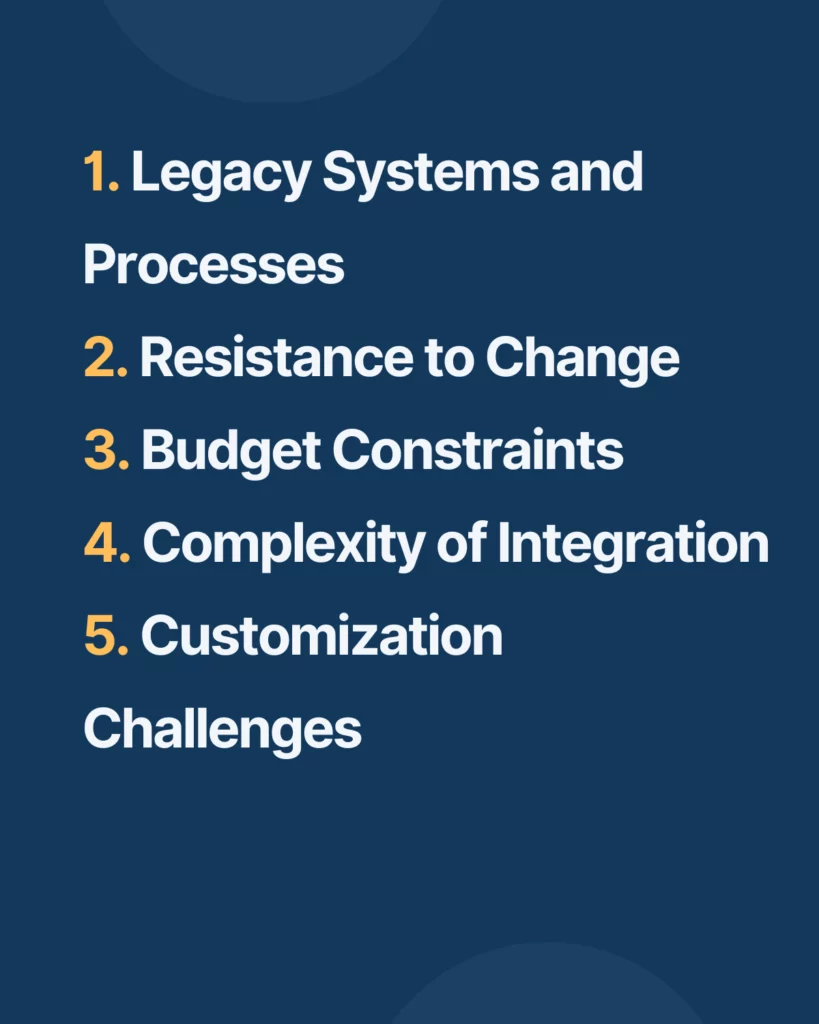

- Legacy Systems and Processes: Manufacturing sectors frequently employ decades-old legacy systems and procedures. Making the switch from these well-established techniques to digital solutions can be difficult, time-consuming, and expensive..

- Resistance to Change: Employee resistance to change may be brought on by unfamiliarity or a worry that they may lose their jobs if they accept new digital tools and processes. For digitization to be successful, there must be a cultural shift toward accepting technology.

- Budget Constraints: Putting digital technologies into use necessitates a monetary commitment for training, software, hardware, and ongoing maintenance. Budget constraints may cause digitization efforts to stall or slow down.

- Complexity of Integration: Integrating digital solutions with current systems, equipment, and processes can be difficult. Although it can be technically challenging, ensuring continuous data flow and interoperability is essential.

- Customization Challenges: There are many different manufacturing procedures and standards for quality. It might be challenging to find digital solutions that can be altered to fit individual workflows and requirements.

- Data Security Concerns: Manufacturing data is sensitive and essential to corporate operations, raising data security concerns. Concerns about cybersecurity can impede the adoption of digital technology, thus ensuring data security and compliance with industry standards are priorities.

- Lack of Expertise: Skilled personnel who are knowledgeable about both technology and the manufacturing sector are needed for the deployment and administration of digital solutions. Lack of such knowledge can impede advancement.

- Limited Understanding of Benefits: Some businesses might not fully appreciate how digitization would improve quality control. For buy-in, it is crucial to provide a definite return on investment and long-term benefits.

- Risk of Disruption: There is a chance that operations will be disrupted once the switch to digital technology is made. Manufacturers can be wary about how their actions will affect production and product quality.

- Vendor Selection: Choosing the best vendor to meet the business’s demands, constraints, and long-term objectives can be a challenging procedure.

Follow us to know the solutions to overcome the above issues and successfully transform the paper-based traditional quality process into a digital environment.

Digitalization can able to save employees time and improve the profitability of the business. Read our other blog about ” From Manual to Digital: Making The Shift in Quality Management Processes ”