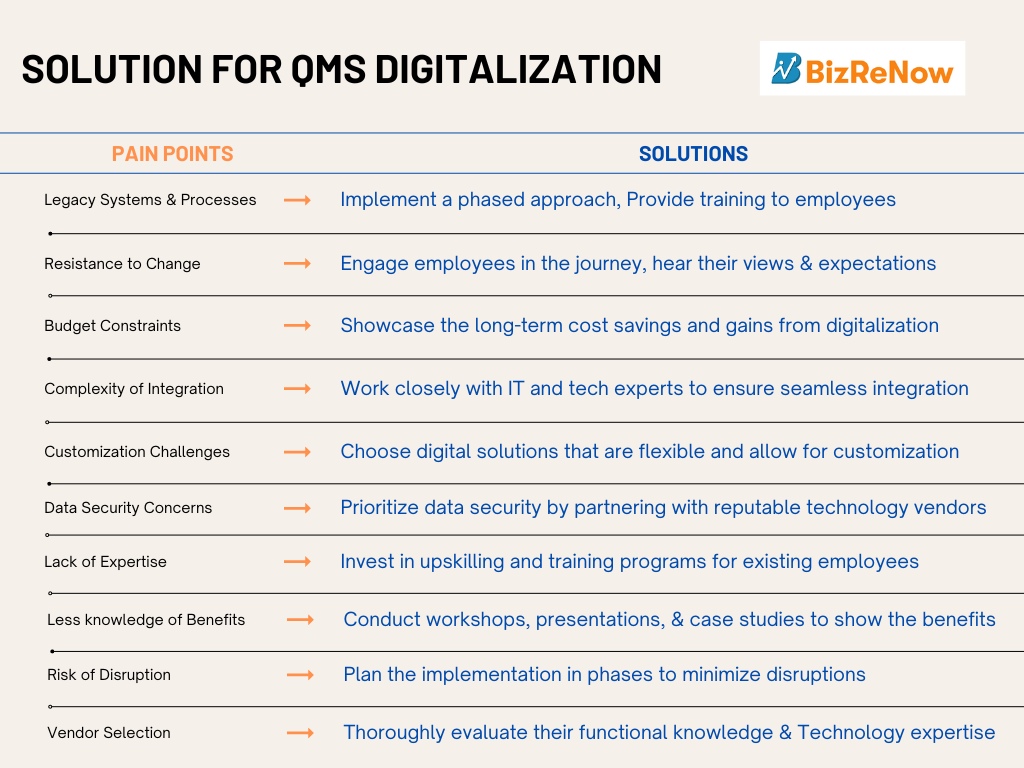

Amidst the evolving landscape of manufacturing, the integration of Quality Management System (QMS) software emerges as a pivotal solution. Despite the potential advantages of digitization, challenges persist in fully embracing these transformative tools. Legacy systems, resistance to change, and budget constraints hinder progress. However, the potential to surmount these hurdles is within reach. This article delves into pragmatic strategies for addressing these pain points, empowering manufacturing industries to leverage QMS software for streamlined quality processes and enhanced operational efficiency.

We are going to explore the solutions for the challenges discussed earlier (read here).

- Legacy Systems and Processes: Adopt a staged strategy by progressively incorporating digital technologies alongside current systems. Employees will transfer more easily if you give them thorough training on the advantages and use of new technologies.

- Encourage a culture of creativity and learning within the organization to combat resistance to change. By emphasizing the ways in which new tools improve their job and advance their professional development, you may involve your staff in the process of digitization.

- Budgetary Restraints: Outline the efficiency and cost savings that can be achieved over the long run through digitalization. Investigate cost-effective alternatives, look for outside funding sources, and order your technological investments according to their potential impact.

- Integration Complexity: To enable seamless integration of digital solutions with current systems, work closely with IT and technology specialists. Choose tools with reliable APIs and interoperability.

- Customization Obstacles: Opt for adaptable digital systems that enable customisation to fit certain industrial operations. Work together with technology vendors to customize the tools to the unique requirements of the firm.

- Concerns about data security: Put a high priority on data security by working with trusted technology vendors who provide reliable security upgrades, strong encryption, and adherence to industry standards.

- A lack of expertise: Invest in initiatives that will upskill and teach current staff. To assist with the administration and implementation of new solutions, consult or hire specialists in digital technology.

- Limited Understanding of Benefits: Conduct case studies, workshops, and presentations to show the practical advantages of digitization. Showcase how technology increases productivity and quality using real-world examples.

- Risk of Disruption: To reduce interruptions, plan the deployment in phases. Run pilot projects to find potential problems and guarantee a smooth transition that doesn’t interfere with essential manufacturing procedures.

- Vendor Selection: Carefully assess possible technology vendors, taking into account their track record, client testimonials, and capacity for continuous assistance. Select partners who share the objectives of the organization.

Connect to us to know / understand how we can able provide the right affordable, user friendly solution as recommended above with our QMS Software (Quality Management System Software). Book a demo here