What is QMS ??

The quality Management system is a system that focuses to deliver the customer requirements with the topmost satisfaction level and documenting all the processes followed in a corporation to form its function without being man dependent.

The importance of Quality involves serving the purchasers with an equivalent level of quality all the time to all or any the purchasers. QMS helps to take care of an equivalent process all the time with the documented procedures & an equivalent are going to be verified with levels of inspection, Audits & Reviews.

There are various QMS standards available against to industry types

- General business – ISO9001

- Automotive – IATF16949

- Petroleum & gas – API Spec Q1

- Medical Devices – ISO13485

- Services – ISO20000

- Information Security – ISO27001

- Aerospace – AS9100

All the QMS standards enforce industry-specific requirements instead of general QMS requirements.

ISO 9001 – General QMS

ISO 9001 is defined because of the international standard that specifies requirements for a top quality management system (QMS). Organizations use quality to demonstrate the power to consistently provide products and services to satisfy the customer and regulatory requirements. It’s the foremost popular standard within the ISO 9000 series and therefore the only standard within the series to which organizations can certify.

This was first published in 1987 by the world organization for Standardization, a world agency composed of the national standards bodies of quite 160 countries.

IATF 16949 – Automotive QMS

IATF 16949:2016 may be a technical specification aimed toward the event of a top-quality management system that gives for continual improvement, emphasizing defect prevention and therefore the reduction of variation and waste within the automotive industry supply chain and assembly process. it’s supported the ISO 9001 standard.

About 30 per cent of the quite 100 existing motorcar manufacturers follow the wants of the norm but especially the massive Asian manufacturers have differentiated and have their own requirements for the standard management systems of their corporate group and their suppliers.

API SpecQ1 – Oil & Gas QMS

API Spec Q1 is developed to make sure the businesses follow the QMS process efficiently and it’s published by the American Petroleum Institute (API) titled “Specification for Quality Management System Requirements for Manufacturing Organizations for the Petroleum and Gas Industry”.

This certification is meant for companies who manufacture equipment or components of kit utilized in oil and gas production. Certifications are issued exclusively by API.

Companies must have a top-quality system in situ a minimum of four months before submitting an application. the standard manual must implement each review and risk-mitigation item outlined within the standard, and therefore the full system must be audited per annum to make sure continued conformance to the wants.

ISO 13485 – Medical QMS

It represents the want for a comprehensive quality management system for the planning and manufacture of medical devices. This standard supersedes earlier documents like EN 46001 (1993 and 1996) and EN 46002 (1996), the previously published ISO 13485 (1996 and 2003), and ISO 13488 (also 1996).

ISO 9001 focuses on continual improvement within the business, whereas ISO 13485 requires only that the certified organization demonstrate the standard system is effectively implemented and maintained.

Additionally, the ISO 9001 requirements regarding customer satisfaction are absent from the medical device standard.

ISO20000 – Service QMS

It was developed in 2005 by ISO/IEC JTC1/SC7 and revised in 2011 and 2018. It was originally based on the earlier BS 15000 that was developed by BSI Group. ISO/IEC 20000-1:2018 (‘part 1’) specifies requirements for “establishing, implementing, maintaining and continually improving a service management system (SMS). An SMS supports the management of the service lifecycle, including the planning, design, transition, delivery, and improvement of services, which meet agreed requirements and deliver value for customers, users, and the organization delivering the services.

ISO27001 – Information Security QMS

The standard was originally published jointly by the International Organization for Standardization (ISO) and the IEC) in 2005. It details requirements for establishing, implementing, maintaining, and continually improving an information security management system (ISMS) – the aim of which is to help organizations make the information assets they hold more secure

AS9100 – Aerospace QMS

AS9100 is the international Quality Management System Standard for the Aviation, Space, and Defense (AS&D) industry, created by the IAQG, and AS9100 Rev D (2016) is the most up-to-date version. the quality provides suppliers with requirements for creating and maintaining a comprehensive quality system for providing safe and reliable products to the ASD industry, also as civil & military aviation requirements. “AS9100 Certified” means a corporation has met the wants of AS9100D.

About Digital Quality Management System software

BizReNow Solutions offers DQMS, a free QMS software for the manufacturing, Aerospace, Medical & Automotive industries.

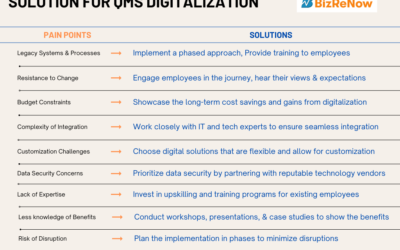

Usage of paper was a major pain point in the implementation of these standards because it called for physical availability of the documents & records in place, Later it is replaced by Excel & Word for the documentation but still, it is a pain point to the employees work on it.

This makes the employees work on repeated work (Clerical / NVA) dragging down productivity by almost 50%.

With our Digital QMS software, a company can implement the QMS standard without Paper, Excel, Word, PPT, Mail, Calls, Messages, Follow-ups, Long meetings.